Safety Is Built In

CSA/UL approved regulator, fuel lines, flame-out sensor and engineered heat shielding work together to create a safer operating experience. Safety

clamps, keep your lid securely

fastened during transport.

Easy To Operate

No more wasting time searching for a striker, lighter or matches. Starting a melter has never been easier with our push button

electric ignition and two independently operated burners.

Reliable

Productive

Melts and applies up-to 50% more hot crack fill per day while using less than half the fuel compared to traditional ‘torch’ fired melter kettles

Model:

RY10MK-Pro

Version:

MLT-0009

Published:

08/05/2020

10-gallon Direct Fired Melter Kettler

The RY10MK-PRO is a portable Crack Fill Kettle designed to be free standing or optionally bolted to any truck or trailer.

Its heavy-duty molasses valve allows you to control the flow of material into any pour-pot or bander. Safety, reliability and

efficiency combine in this machine to create a contractor’s must-have.

Featured In

![]()

Safety Built In

Safer Fuel Lines

Fully Equipped with CSA/UL approved regulator to provide precise control over fuel flow to the kettle.”

Flame-Out Sensor

The sealed burner is equipped with a CSA / UL approved flameout sensor which detects flameouts commonly caused by wind and prevents fuel from flowing to the burner

1/2″ Holes

holes in leg channels allow for safe and easy mounting to any truck or trailer

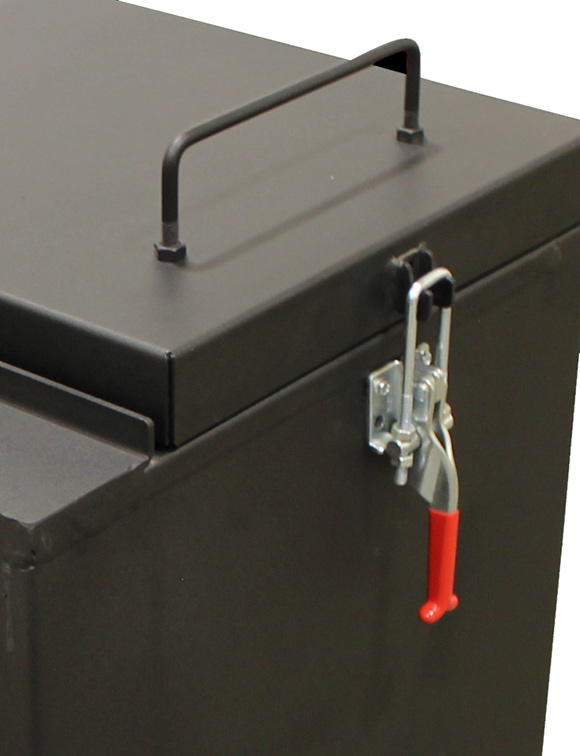

Safety Latch

Kettle is equipped with a latch, which helps keep your lid securely fastened while moving from job to job.

Easy to Operate

Molasses Valve

2″ molasses valve quickly and conveniently dispenses melted crack filler

Manual Agitation

Standard manual agitation allows for easy mixing of material as it melts

Electric Ignition

No more wasting time searching for a striker, lighter or matches. Starting a melter has never been easier with our push button electric ignition

Reliable

Liquid-Filled Thermometer

The unique liquid-filled thermometer is highly resistant to damage caused by constant vibrations during regular use, which ensures a reliable temperature reading every time

Sealed Burner

The enclosed burner design is shielded from the elements and virtually eliminates flame-outs caused by wind, which are common to torch-fired models.

Built-in Strainer

Built-in strainer prevents valve clogs from unmelted pieces of rubber

Productive

%

Faster

Melt crack sealant up to 50% faster than torch-fired models and allows you to apply up to 4800ft of crack filler per day.

Side-by-Side controls reduce operator fatigue, allowing you to get more done in less time.

%

Less Fuel

The Optimized burnet/kettle design provides even heat distribution during the melting process: this eliminates downtime caused by material crystallization common to torch-fired models.

The sealed burner consumes nearly 50% less fuel than traditional torch-fired melter kettles

RY10MK

Melter-Applicator- 101bs/46kgs Assembled

- 14 Gauge Steel

- Powder Coated Steel Frame

- 2″ Molasses Valve

- 150,000 BTU Heating Torch

- 10 US Gallons

- 5PSI Max Fuel Pressure

- Up To 3200 Feet per day

RY10MK-PRO

Melter Kettle- 125bs/57kgs Assembled

- 14 Gauge Steel

- Powder Coated Steel Frame

- 2″ Molasses Valve

- 50,000 BTU Sealed Burner

- 10 US Gallons

- 5PSI Max Fuel Pressure

- Up To 4800 Feet per day

RY30MK

Melter-Applicator- 189lbs/86kgs Assembled

- 14 Gauge Steel

- Powder Coated Steel Frame

- 2″ Molasses Valve

- 150,000 BTU Heating Torch

- 30 US Gallons

- 5PSI Max Fuel Pressure

- Up To 7200 Feet per day

RY30MK-PRO

Melter Kettle- 257lbs/117kgs Assembled

- 14 Gauge Steel

- Powder Coated Steel Frame

- 2″ Molasses Valve

- Dual 50,000 BTU Sealed Burner

- 30 US Gallons

- 5PSI Max Fuel Pressure

- Up To 9600 Feet per day

Ready to Buy?

The RY10 Pro is a must-have for any serious asphalt maintenance contractor.