Safety Is Built In

Easy To Operate

Push Button Electronic-Ignition, Side-by-Side Height Adjustable Controls and a design optimized for one-man operation make crack filling easier than ever.

Reliable

Productive

RY10MA-Pro-V4

Version:

RA-MLT-0013

Published:

08/05/2020

Our Professional grade Melter

The RY10MA-PRO Professional Crack Fill Melter Applicator’s patent-pending design uses up to 50% less fuel than traditional melter applicators – and it’s got built in time-saving innovations, too.

Featured In

![]()

Safety Built In

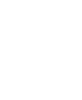

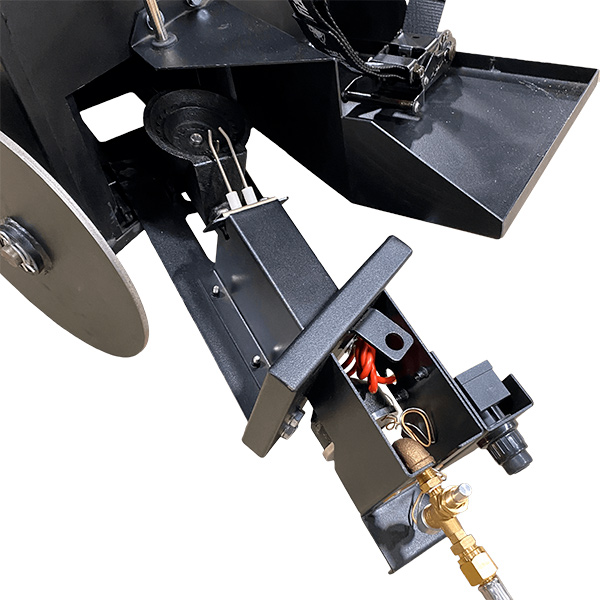

Safer Fuel Lines

Fully Equipped with CSA/UL approved regulator to provide precise control over fuel flow to the kettle.”

Flame-Out Sensor

The sealed burner is equipped with a CSA / UL approved flameout sensor which detects flameouts commonly caused by wind and prevents fuel from flowing to the burner

Heavy Duty Ratchet Strap

Features a heavy-duty ratchet strap to secure the propane tank.

Safety Latch

Kettle is equipped with a latch which help keep your lid securely fastened while moving from job to job.

Adjustable Handlebars and Controls

Handlebars are adjustable from 35″- 42″ – optimize valve squeeze distance and spring tension to reduce operator fatigue.

Easy to Operate

Valve Tension Adjustment

Valve control arm allows for adjusting the spring tension for optimal performance.

Side by Side Controls

Side-by-side controls, which include on-the-fly agitation, help the operator control agitation, flow, the application of material, view and adjust temperature, all without leaving the operating position.

Electric Ignition

No more wasting time searching for a striker, lighter or matches. Starting a melter has never been easier with our push button electric ignition.

Reliable

Liquid Filled Thermometer

The unique liquid filled thermometer is highly resistant to damage caused by constant vibrations during regular use, which ensures a reliable temperature reading every time.

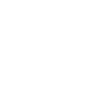

Double Ball Bearing Wheels

Rear wheels feature double ball bearings for increased stability and smooth operation.

Dual Front Casters

Two solid front casters allow the operator to maneuver over slanted surfaces with increased stability.

Sealed Burner

The enclosed burner design is shielded from the elements and virtually eliminates flameouts by wind, which are common to torch-fired models.

Productive

%

Faster

%

Less Fuel

RynoValve™

RynoValve™ requires virtually no preheating time and is ready to use as soon as you have hot sealant in the kettle, saving you time between jobs.

RY10MA

Melter-Applicator- 142lbs/65kgs Assembled

- Powder Coated Steel Frame

- Standard Agitation

- 150, 000 BTU Heating Torch

- 12.5 Gallons

- 30PSI Max Fuel Pressure

- Up To 3200 Feet per day

RY10MA ERGO

Melter Kettle- 148lbs/67kgs Assembled

- Height Adjustable Controls

- Powder Coated Steel Frame

- On-The-fly Agitation

- 150, 000 BTU Heating Torch

- 12.5 Gallons

- 30PSI Max Fuel Pressure

- Up To 3200 Feet per day

RY10MA PRO

Melter-Applicator- 159lbs/72kgs Assembled

- Height Adjustable Controls

- Powder Coated Steel Frame

- Double Front Casters

- On-The-Fly Agitation

- 50,000 BTU Sealed Burner

- 12.5 Gallons

- 5PSI Max Fuel Pressure

- Up To 4800 Feet per day

RY10MK ELITE

Melter Kettle- 168lbs/76kgs Assembled

- Height Adjustable Controls

- Powder Coated Steel Frame

- Double Front Casters with Lift Handles

- RynoDash™

- Included Torch Kit

- On-The-Fly Agitation

- 50,000 BTU Sealed Burner

- 12.5 Gallons

- 5PSI Max Fuel Pressure

- Up To 4800 Feet per day

Ready to Buy?

The RY10 Pro is a must-have for any serious asphalt maintenance contractor.